Instant coffee manufacturers have taken big leaps and bounds in their processes to improve the flavours of their products. Paul Ahn, Sales Manager at global technology manufacturer Flavourtech, says it’s due to the demand shift from consumers for higher quality and better flavoured products.

“Consumer preferences change, and it has been more evident in the last few years,” Ahn says. “We are seeing an increasing demand for high quality natural flavours, which is tied in with an increase in healthy living.” Flavourtech has approached this shift capturing the flavour notes through a natural process. “Whether it is coffee, tea, fruits, vegetables or spices, we are able to capture their desirable natural aroma through our systems from the raw material itself where they are freshest and best.”

The instant coffee manufacturing process has not changed significantly for decades. Typically, it has involved high temperatures for extraction with long residence times, leading to loss or damage to the delicate roast and ground notes. “The two combined conditions can also mean the introduction of undesirable burnt notes, which can ruin a cup of coffee.”

“The difference to the Flavourtech way when compared to other soluble coffee systems is the way we treat the process. It begins with the raw material itself, the roasted beans. We capture the desirable, natural, aroma notes upfront using the Spinning Cone Column also known as the SCC. These notes are then protected at low temperatures while the deflavoured coffee beans then go through a high temperature extraction step, but in this case, it is for only 20 minutes compared several hours in other systems.” A combination of upfront flavour capture through the SCC and less time of extraction equates to higher quality flavour notes without the undesirable burnt notes.

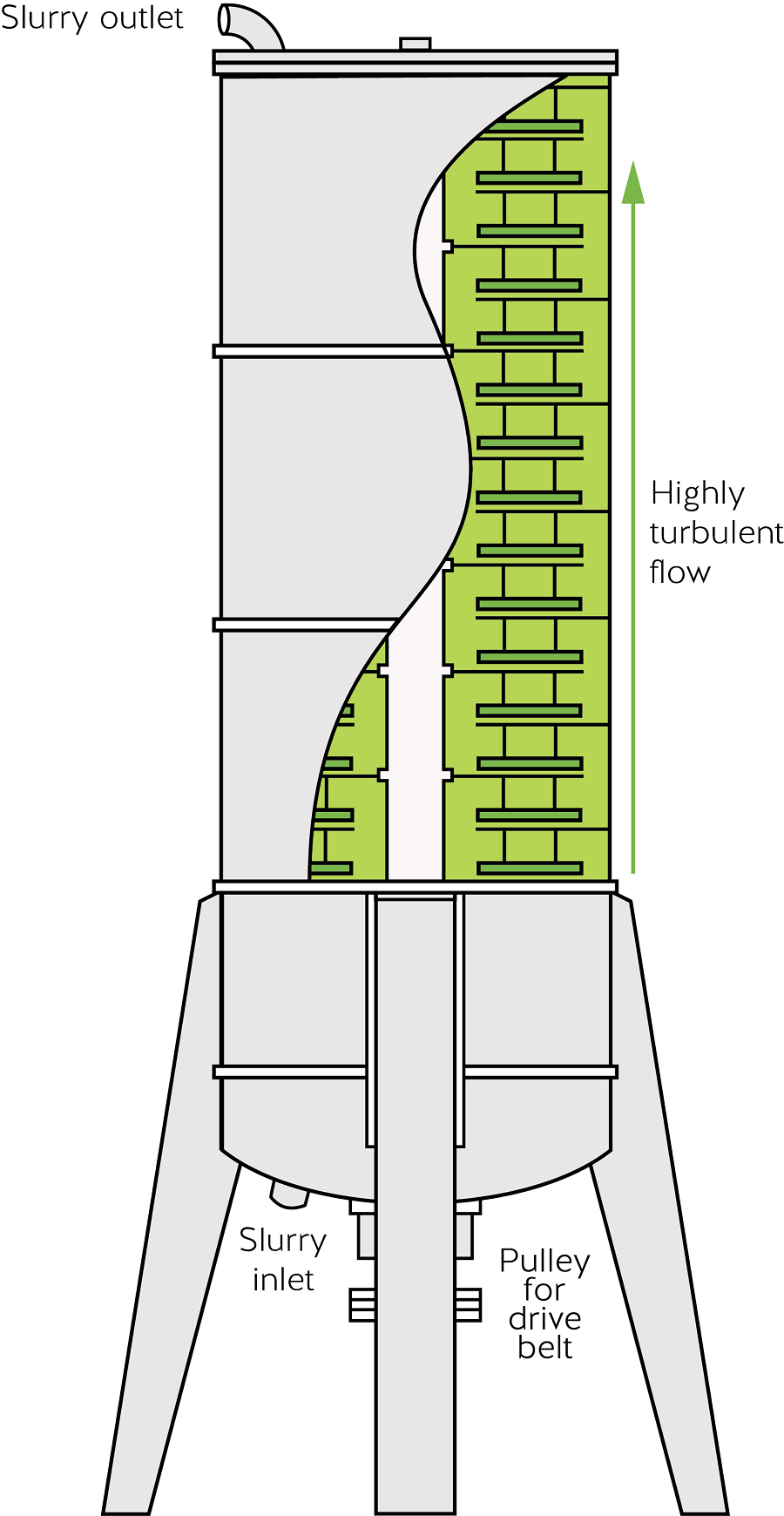

How does Flavourtech extract coffee at high temperatures (in the range of 150 to 195°C) but with significantly lower times? Through using its unique Rotating Disc Column (RDC).

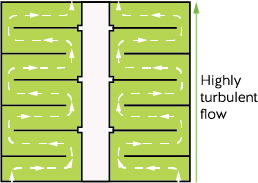

“The RDC was designed with the product in mind, the milled roasted beans,” says Tim Birks, Sales Manager of Europe and Africa, Flavourtech. “Our engineering department worked tirelessly to develop the RDC, an extraction column, which approaches plug-flow. This equates to a more consistent and shorter extraction process, and can be used in a continuous manner.”

Flavourtech systems such as the Spinning Cone Column and the Centritherm® evaporator have spinning cones, all designed to reduce the thermal impact on the product. The RDC internals are similar, but rather than spinning cones there are spinning baffles. Sets of alternating spinning and stationary baffles comprise the RDC. “The milled roasted beans and in the form of a slurry, are then pumped through the RDC under pressure from the bottom of the column to the top in only 20 minutes. Extraction is quick, efficient and, when placed inline in the Integrated Extraction System (IES), is continuous and automated,” says Birks

The combination of the SCC and RDC have been milestones in soluble coffee production. Flavourtech has shown by utilising the engineering know-how and a passion for natural flavours, they have been able to enhance the flavour profiles of instant coffee, and many consumers have benefited. “The unique flavours of single-origin coffee such as Colombian, Ethiopian and Guatemalan, are carried through to the final product, to the powder itself. The flavours are intense and authentic.”

The Flavourtech IES process assists instant coffee producers maintain the flavours from the raw material with the ability to control temperature and thus reducing the thermal impact of the coffee. The unique processing involves:

- Roasted coffee beans are milled under a blanket of cold water through the Slurry Preparation Module. The water acts as a carrier for these volatile aroma components and carries (with the slurry) to the Spinning Cone Column (SCC).

- Brewing or extraction temperatures of 100oC occur in the SCC, for only 30 seconds (compare this to other techniques where it could be in the many minutes to hours). The slurry, consisting of the beans and water, all pass through from the top to bottom of the column in 30 seconds, steam is used to gently brew the coffee as well as strip out the natural aroma from the beans and slurry where it leaves the SCC, condensed and stored in a chilled vessel. These are the natural and desirable R&G notes.

- Post the SCC, if further high temperature extraction is required the Rotating Disc Column (RDC) can help to further extract the solids – the time of extraction is only 20 minutes rather than hours. The process involves rotating baffles and a continuous flow of the coffee slurry, all performed post the SCC where the R&G flavour notes have been previously removed and stored.

- The slurry then enters a Clarification Module to separate the coffee beans from the aqueous extract.

- This extract can then be used for RTD with the natural flavours (captured as shown above) added back to produce a full-flavoured beverage or can be concentrated through Flavourtech’s unique Centritherm® evaporator (CT) to produce a concentrate. The CT has only 1 second heat contact time on the product and the low evaporation temperature of 50°C means no damage to the tea/coffee colour, bioactives or the flavours

- The coffee concentrate can also be mixed with the aroma and spray or freeze dried to produce a powder with the highest level of R&G coffee flavours.

- The IES can also handle cold-brew coffee (at lower process temperatures) quickly, is automated and continuously producing consistent results.

“The RDC not only helps in providing a highly efficient extraction process, but when combined with other Flavourtech technologies comprising the IES, produces instant coffee full of the natural R&G notes of the roasted beans,” concludes Ahn.

For more information, visit www.flavourtech.com