The Millennials and Gen Zs have the right idea – look after your body, your health and the planet you live on and they all will then look after you. The excesses and indulgences from previous generations have now been superseded by health, nutrition and sustainability. But it goes further than this with the rise of “functional foods,” or ingredients that provide health benefits beyond that of basic nutrition. Examples of stated benefits include relief from stress or anxiety by drinking certain herbal teas. This is where medicine and food have a common origin and purpose.

Functional foods can be classified as the foods that already contain naturally – or have been fortified with or synthesised to contain – beneficial ingredients (bioactives), or the removal of ingredients that do us harm such as allergens. Foods and beverages containing beneficial bioactive compounds are now increasing in popularity and are being sought after, just take a look at your local grocery store. They are typically at a premium price that consumers are willing to pay. But when it comes to manufacturing of these food and beverages some care must be taken to preserve these valuable bioactives. For example, the extraction or synthesis of sought after compounds or components may require either water or solvent, followed by the removal of this liquid so as to isolate these valuable components, undamaged, in order to give these functional foods a chance to do good in our bodies.

Flavourtech, an Australian manufacturer of food and beverage process systems, has been assisting manufacturers around the world in providing the means to produce the best quality ingredients with the highest levels of natural flavours and active ingredients for over 35 years. Examples of such products are in the pharmaceutical, nutraceutical, food and beverage industries. Flavourtech realised early on that the best way to get the best from products, whether it be flavour or active ingredients, is to obtain it from processing the raw material when it is freshest and best (eg. flavour from roasted coffee beans, tea leaves, flavour recovery and protection for award winning wines and beers), and the concentration of solution through a gentle yet efficient evaporation process. Their processes involve shorter residence times to reduce the thermal impact when compared to other processes so as to maintain the quality of the end product, that is, the preservation of the bioactives.

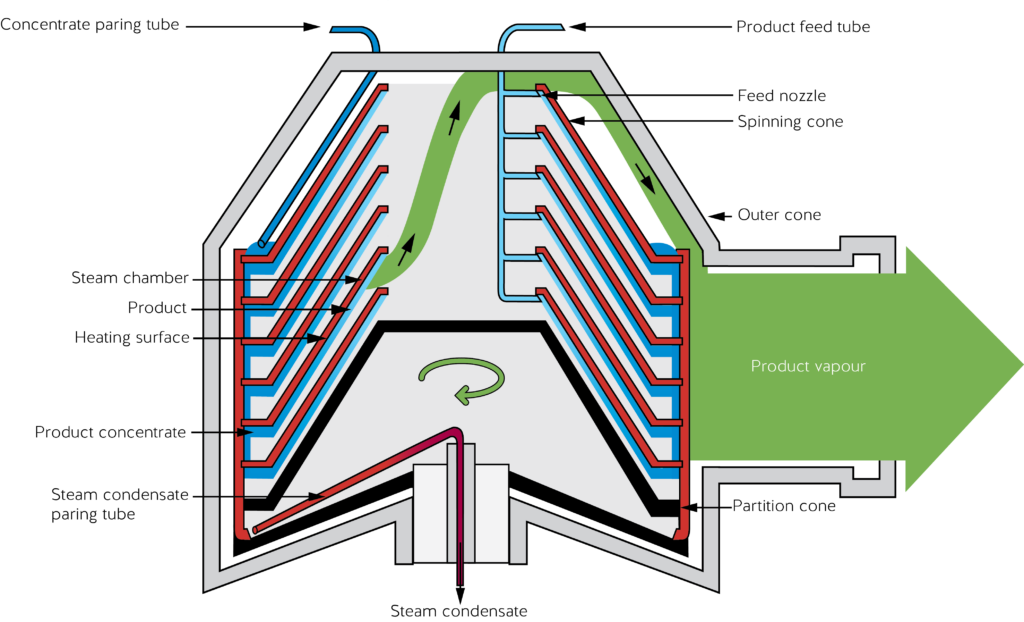

Flavourtech has approached this requirement with its Centritherm® evaporator (CT) and its commitment to high quality through low residence times and low operating temperatures. The CT was first developed from a requirement to concentrate a solution that was prone to high temperature damage. By utilising spinning cones and centrifugal force, the time the product undergoes concentration has been minimised to approximately 1 second.

Let’s take a closer look – the product to be concentrated is deposited on the underside of these spinning cones where it forms a thin layer. The operating temperature is approximately 50°C but due to both of the above features, the evaporation process is quick and gentle (Figure 1). To visualise the feature of thin-film technology, imagine a cup of water on a table. It will evaporate slowly at room temperature, but if the water is poured onto the table as a thin film then the evaporation process will occur much faster.

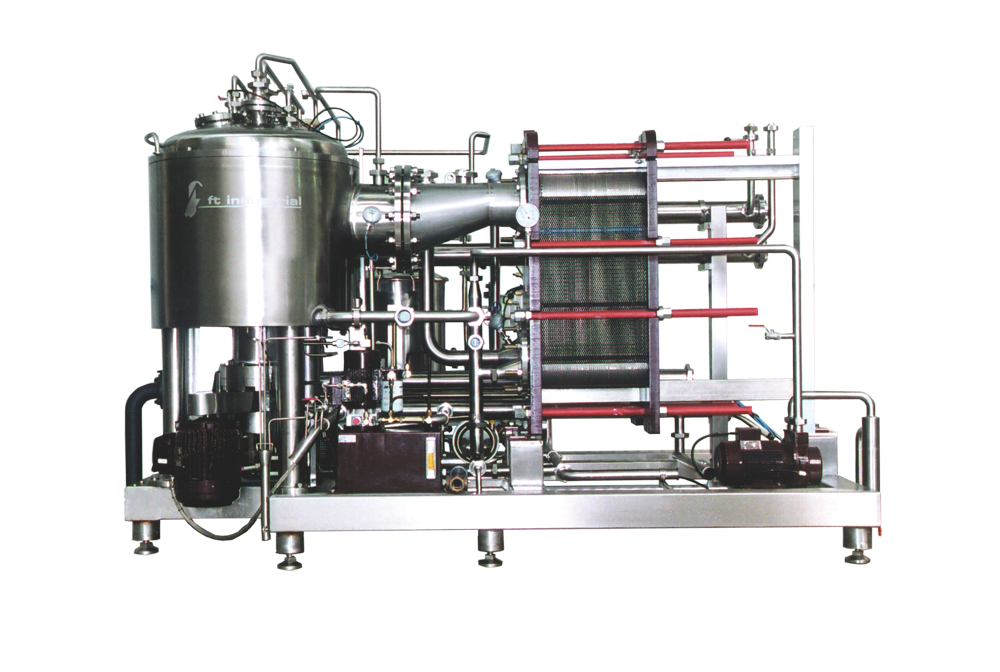

The Centritherm evaporator (Figure 2) does come in many sizes and with varying evaporation capacities to suit, from a single-cone CT1-09RM for smaller production or R&D runs, to the large 12-cone CT12-130FA to meet high volume demands.

Take, for example, antioxidants such as anthocyanins found in many red to purplish blue-coloured fruits and vegetables are at times prone to damage during manufacturing processes when there are high temperatures involved. The CT, with the low thermal residence time and low operating temperature, combine to give the antioxidants the best conditions for survival and then to do their best work in the human body, retaining high levels of the antioxidants in the final concentrate.

An application is in the concentration of juice containing high levels of these anthocyanins such as blood oranges or red grapes. Using any other evaporators without spinning cones will lead to thermal damage and loss of these antioxidants.

There are manufacturers already with the technologies to meet this demand head-on, providing people of every generation with more choice, more health, better flavours and more health benefits. If you would like to be one of the leaders in this field then please contact Flavourtech.

For further details, please visit https://flavourtech.com/