It is estimated one third of food produced is either lost or wasted between the farm and the plate according to a 2019 report by the World Resources Institute (WRI).* This report highlights where these losses have come from – in the various stages of the food supply chain, including the farm, production, handling and storage, distribution and market and finally from the stage of consumption.

In North America and Oceania 21% of wastage is attributed to the production step alone. In order to reduce food wastage, the United Nations (UN) has set goals, or Sustainable Development Goals (SDG), with a timeframe to achieve them by 2030. An example of a benefit from this goal of reducing food waste is the preservation of valuable ecosystems rather than turning them into unrequired agricultural lands and still being able to feed the population.

Flavourtech, a manufacturer of food and beverage process systems in Australia, has been assisting manufacturers in reducing waste, and the associated impact on the environment, and partake in the closed loop economy.

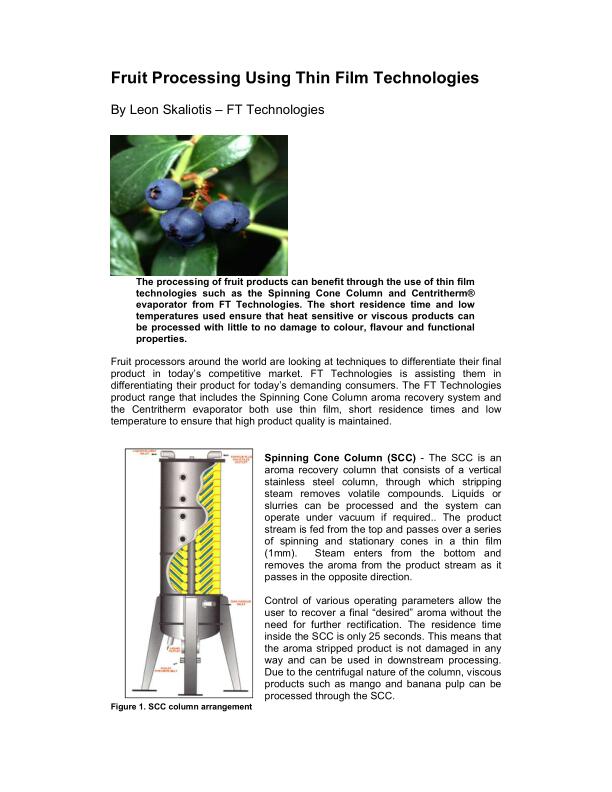

One of the systems they produce is the Spinning Cone Column (SCC), a vacuum steam distillation column, typically used by multinational flavour companies for flavour extraction from fruits, vegetables, herbs, spices, coffee and tea. These flavours are of high quality due to the unique nature of the process – use of centrifugal force by spinning cones to form thin films of liquid, slurry or puree and steam to strip the volatile flavour compounds where it is condensed and then used in other parts of the manufacturing process.

Where this technology can help further is in reducing food wastage by extracting more of the flavours or essential oils from the waste stream or process water during food or beverage manufacturing. For example, in fruit juice concentration, the evaporate or condensate does contain the light aroma volatiles of the fruit that can be captured by the SCC, which can then be used to fortify foods or beverages that require that extract boost. Furthermore, the water stripped of the volatiles is cleaner and so can be reused or recycled. Also, the skins of the fruit that are normally thrown away, can be processed through the SCC to capture their unique flavours and or oils for further use such as in natural food flavouring.

Another example is with the use of their unique evaporator, the Centritherm® (CT), which also utilises spinning cone technology (centrifugal force producing thin films) to safely concentrate solutions to higher levels, taking only one second, while maintaining the integrity of the feed material.

This is importantly so in the ready to drink market where the bottling plants are located some distance from the extraction plant, so transporting concentrates are far more cost effective and more environmentally friendly (lower emissions) than transporting whole product, which is basically then transporting large volumes of water.

Another way the Centritherm evaporator assists in reducing the impact on the environment during food manufacturing is in the production of instant coffee where there is a dependence on an energy intensive spray dryer to form the powder. Usually this energy is derived from the burning of gas or other material to evaporate the water from the coffee extract, more water in the extract means more energy is required to remove it. By concentrating or reducing the water content in the extract as much as possible, while staying within the limit to avoid introducing any damage to the extract (such as to the antioxidants, the colour or flavour), it is possible to lower the energy consumption from the spray dryer and reduce the impact on the environment.

Mustard seeds produce great oils used in many Indian cuisines and are generally produced from cold pressing the seeds. The oil expelled seeds or mustard meal would require disposal and was initially sent to farms for feed material. But due to a reaction with water it was found that the meal produced a compound called Allyl Isothiocyanate or AITC. AITC is a colourless oil and a compound that causes the burning sensation when eating the wasabi in sushi, a highly desired product in Japanese cuisine. Flavourtech’s Integrated Extraction System (IES) is an integrated, inline, continuous, and automated process that allows food and beverage manufacturers to streamline their operations, examples are in coffee and tea (RTD and soluble) production. In the case of mustard meal, the IES that includes the Rotating Disc Column (RDC) and the Spinning Cone Column (SCC) operating in series, is used around the world to extract the AITC from used mustard seed meal to produce this colourless, valuable oil, which can then be sold to food companies for flavour addition, while the meal (previously rejected by the farm animal) can now be eaten.

As we see the human population increasing, there is a greater demand on supplying food to feed them. This places immense pressure on the environment, from the availability of the natural resources to the pollution created from waste and inefficiencies from production. We can all help reduce the impact, be more efficient, recycle where we can and reduce the waste so future generations can enjoy living on this planet like we have.

For further details, please visit Flavourtech.com

*https://files.wri.org/d8/s3fs-public/reducing-food-loss-waste-global-action-agenda_1.pdf